|

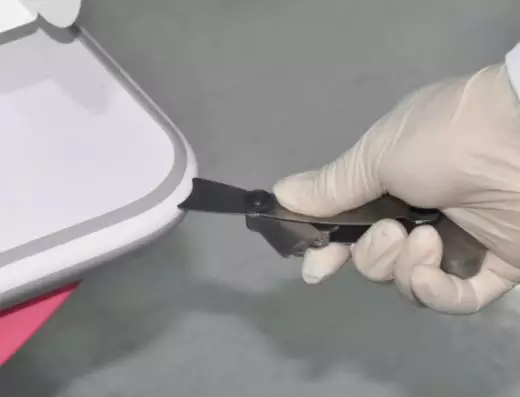

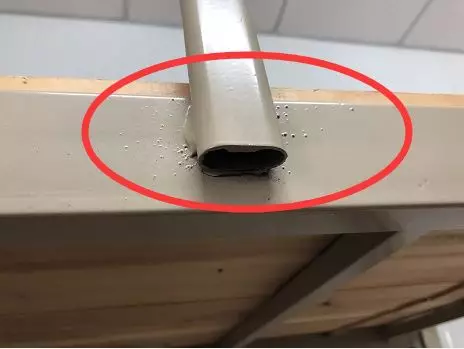

Shipment Inspection of high-end furniture products is part of the quality management system. Because products that pass the inspection will represent the brand of high-end furniture companies directly into the product trading market. Therefore, how to do a good job of product shipment inspection is a matter that all high-end furniture companies must attach great importance to,and it should be a basic required course for all high-end furniture companies.Today Interi Furniture will give you an overview of the quality risk points of several major categories of high-end furniture to help furniture companies better conduct shipping inspections. For children's furniture, the most common risk points are dangerous external corners, holes and gaps, sharp edges and tips, squeeze / cut points, warning signs, and more. High-end furniture factories need to have accurate product checklists and master key indicators of children's bunk beds and other related knowledge about the quality of children's furniture when producing children's furniture. Friends who are interested in this knowledge can pay attention to the content of our next article, and we will introduce it in detail for you. For high-end solid wood furniture, the most common risk points are mainly the requirements for furniture wood processing and the physical and chemical properties of the paint film. In the requirements for furniture wood processing, except for some processing defects, the main unqualified process is that the non-interfacing surfaces of the wood-based panel components are not edge-sealed or painted. For example, the bottom of the drawer is made of plywood, but some edges of the bottom are exposed, and there is no edge sealing or painting treatment. For the physical and chemical properties of paint films, the main unqualified processes are paint film impact resistance, paint film adhesion, paint film resistance to dry heat, and paint film wear resistance. For high-end upholstered furniture, its main unqualified points are the overall dimensions of the furniture product, the physical properties of the sponge, the mechanical properties of the product, and environmental protection performance. At present, the environmental performance requirements of sofas and soft beds are blank in many countries' light industry standards, which has led many high-end furniture companies to easily ignore their environmental performance in their production processes. For high-end metal furniture, although there are relatively few companies producing such furniture, there are many product types and related product standards, so metal furniture manufacturers need to be familiar with more production standards and product requirements. ccording to some statistics, the main unqualified points of metal table and chair products are reflected in the uncovered hole size, unsealed ends of metal pipe fittings, and poor stability of the chairs. The bunk beds are mainly reflected by the size of the guardrail and the ladder not meeting the standard requirements; The office chair mainly reflects the unqualified durability of the casters; the file cabinet mainly reflects the strength test of the shelf support, the strength test of the sliding member, and the vertical static load test of the sliding door. In summary, many cases that fail to meet the standard requirements can actually be avoided before the furniture is shipped.For example, the appearance ends of metal pipe fittings are not sealed, furniture companies should find and correct them when inspecting the appearance of this product; the depth of the sofa seat should be between 480mm and 600mm, which can be verified by measuring with a gage;Holes and gaps in children's furniture can be checked with probes and more.The main reason for the above cases is that these furniture companies do not pay attention to the national furniture production standards or do not understand the standards, which has led them to deviate from the standards in product design, raw material procurement and production processes,and ignore the importance of quality control to the entire production chain. As far as China's furniture production standards are concerned, if the standard requirements are to be classified, it is recommended to divide them into: appearance dimensions, physical and chemical properties, safety requirements, mechanical properties, limits of hazardous substances and product instruction manuals. At the same time, furniture products should be manufacturered according to standards in the product design, raw material procurement and production processes.Then, when the furniture factory arranges the final furniture factory inspection, it needs to confirm all aspects of its standard performance to prevent inferior products from entering the market. So how should a high-end furniture company carry out factory inspection? The main points should be as follows: First, for the products produced by high-end furniture factories, they should be familiar with various standards related to the products; Second, as mentioned above, high-end furniture companies should collect the risk points of various products during the testing process and use them as guidelines for factory inspection; Third, with regard to risk points, high-end furniture companies should set up a "checklist for furniture shipments" in accordance with industry and shelf production standard requirements. The checklist generally includes inspection items, standard requirements, testing tools, testing graphics and testing results . In the end, the success of the plan depends on execution.The quality control department of high-end furniture manufacturers should put everything into practice. The above content is mainly to guide high-end furniture companies to carry out furniture factory inspections in a more targeted manner, to control the quality management system well, and to prevent inferior products from entering the market. As there are too many categories of furniture products and standards involved, we only provide directional guidance here without detailed descriptions. If you have any questions, please feel free to communicate with us through email .

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

TAGS

All

Archives

May 2024

|

RSS Feed

RSS Feed